Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

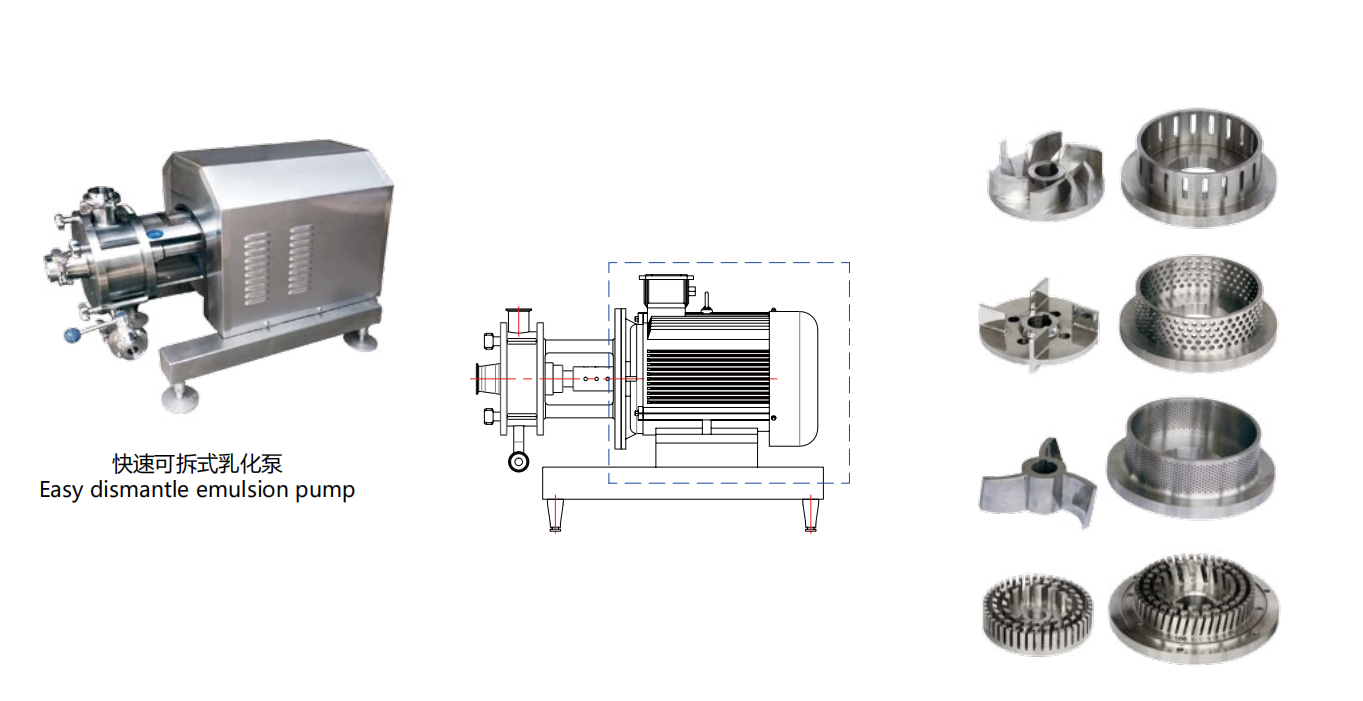

Our sanitary high shear emulsifying pump is designed to deliver exceptional performance and reliability in emulsifying and homogenizing applications. It is a vital component in processes such as cream production, sauce emulsification, and cosmetic formulation. This emulsifying pump is built to meet the highest hygienic standards, ensuring product safety and integrity throughout the emulsification process.

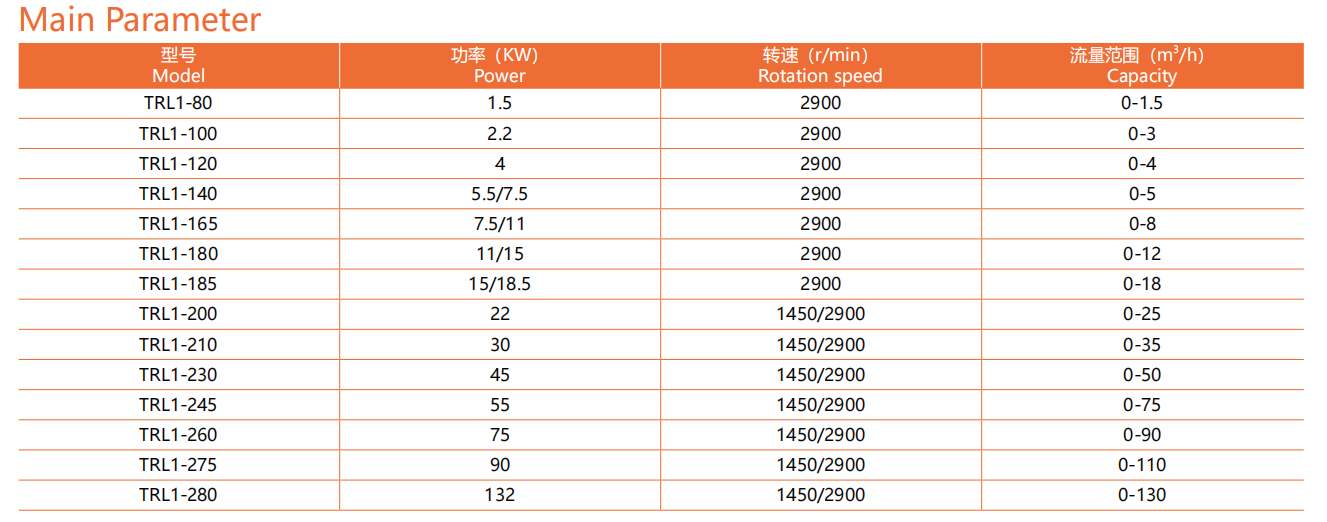

Product parameter

| Product Name: | Sanitary emulsifying pump |

| Material: | SS304 / SS316L / 1.4301 / 1.4404 |

| Seal Gasket: | EPDM FPM(Viton) and NBR |

| Max. Flow: | 140 m3/h |

| Impeller: | Open type impeller |

| Max. Flow: | 140 m3/h |

| Impeller: | Open type impeller |

| Max. Head: | 70M (7bar) |

| Temperature | -10~140 °C(14~284°F) |

| Motor power: | 1.5kw~30kw |

| Mechanical seal: | SIC/C/EPDM (Standard), C/SIC, TC/TC |

| Voltage: | 110V, 220V, 380V |

| Motor: | ABB/SIEMENS |

| Motor Frequency: | 50HZ, 60HZ |

| Available connection: | Clamped, Threaded, Flanged |

The sanitary emulsified pump is a cutting-edge solution designed for emulsifying and homogenizing applications in hygienic industries. This high shear emulsifying pump is specifically engineered to meet the stringent requirements of industries such as food and beverage, pharmaceutical, and cosmetics, where precise emulsification and homogenization are essential. With its advanced features, hygienic design, and numerous advantages, it is the ideal choice for industries that require efficient and consistent emulsification processes.

Product drawing

Product Features

Product Advantages

1.Enhanced Product Quality: The advanced emulsification technology and high shear capability of the high shear emulsifying pump contribute to enhanced product quality. It enables the creation of emulsions with superior texture, stability, and flavor, resulting in a premium end product that meets the highest standards of excellence.

2.Enhanced Operational Efficiency: With its efficient emulsification process and adjustable parameters, this pump significantly reduces process time and increases production efficiency. It allows for faster batch cycles and higher throughput, enabling businesses to meet growing demands and maximize productivity.

3.Economical Benefits: The sanitary emulsifying pump offers cost savings through its energy-efficient operation and reduced product waste. Its high emulsification efficiency ensures optimal utilization of ingredients, minimizing product loss and maximizing yield. Additionally, the pump's low maintenance requirements and easy cleaning procedures contribute to overall cost savings.